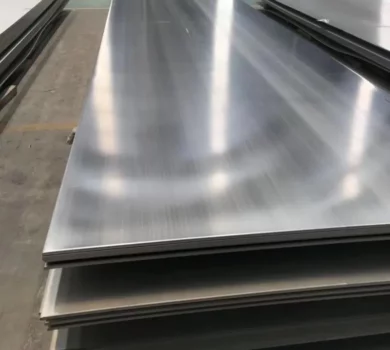

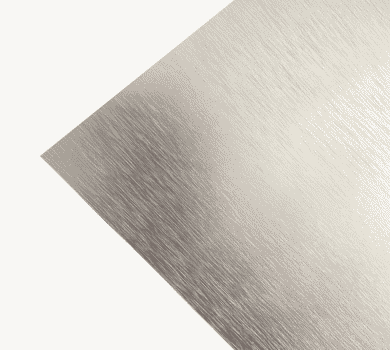

1050 Aluminum Sheet

Our 1050 Aluminum Sheet has been meticulously crafted to cater to the specific needs of businesses engaged in the packaging, electronics, and aerospace industries within the realm of industrial materials. Its lightweight properties and ease of processing make it a versatile choice for various applications across these diverse sectors. It assures durability and reliability through its exceptional electrical conductivity and corrosion resistance. Additionally, our seamless export system and adaptable payment options are designed to simplify your procurement process and ensure convenience.

We understand the pivotal role that material quality plays in your operations, and our 1050 Aluminum Sheet is engineered to not only meet but exceed your exacting standards. Its performance and versatility make it a practical choice, while its corrosion resistance guarantees longevity. With our commitment to a flawless export process and flexible payment alternatives, we aim to be your trusted partner in providing the materials you need. We encourage you to explore the possibilities offered by our product and anticipate the service we are eager to provide.

Applications:

1) Aircraft, automobile, train

2) Building wall, ceilings, furniture cabinet, lighting plate

3) Shipping plate, solar reflective plate, Corner protector, insulation material

4) Beverage bottle, cap, ring-pull, cosmetics shell and cover

5) Aluminum tread/embossed plate, quenched and pre-stretched plate

6) PS baseplate, CTP baseplate, Signs, nameplate

7) Electrical products shell, engineering machinery plate

8) Aluminum reefer containers and special containers, etc.

9) Spinning, Auto, etc.

10) Printed aluminum sheet

11) Aluminum Sheet For Bus Skins

look more about our B2B website