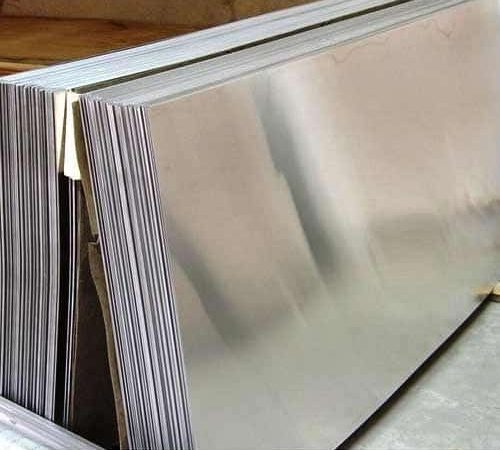

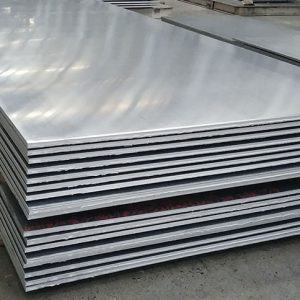

Customers in the shipbuilding, rail car manufacturing, tip truck body construction, automobile bodywork, and pressure vessel industries can rely on our 5083 Aluminum Sheet to meet their specific needs. These 5083 Aluminum Sheets exhibit exceptional resistance to seawater corrosion, ensuring long-term durability in maritime conditions. They are also highly moldable, stampable, and weldable, offering versatility in production operations. Their outstanding weldability simplifies key component assembly. Furthermore, our marine certification underscores our commitment to quality and safety compliance. We prioritize short lead times and unwavering quality to ensure that our product consistently meets your high expectations.

Our 5083 Aluminum Sheet stands as a trustworthy choice in shipbuilding, rail car manufacturing, tip truck body construction, vehicle body production, and pressure vessel fabrication. Its exceptional resistance to seawater corrosion guarantees the longevity and strength of your structures in harsh marine conditions. The ease of forming, stamping, and welding allows for greater design and assembly flexibility, while the marine certificate verifies our product's suitability for maritime applications. We understand the importance of on-time delivery and consistent quality, and we are dedicated to providing you with a reliable supply of 5083 Aluminum Sheets that meet your demands, enabling your success in your endeavors.

Applications:

1) Aircraft, automobile, train

2) Building wall, ceilings, furniture cabinet, lighting plate

3) Shipping plate, solar reflective plate, Corner protector, insulation material

4) Beverage bottle, cap, ring-pull, cosmetics shell and cover

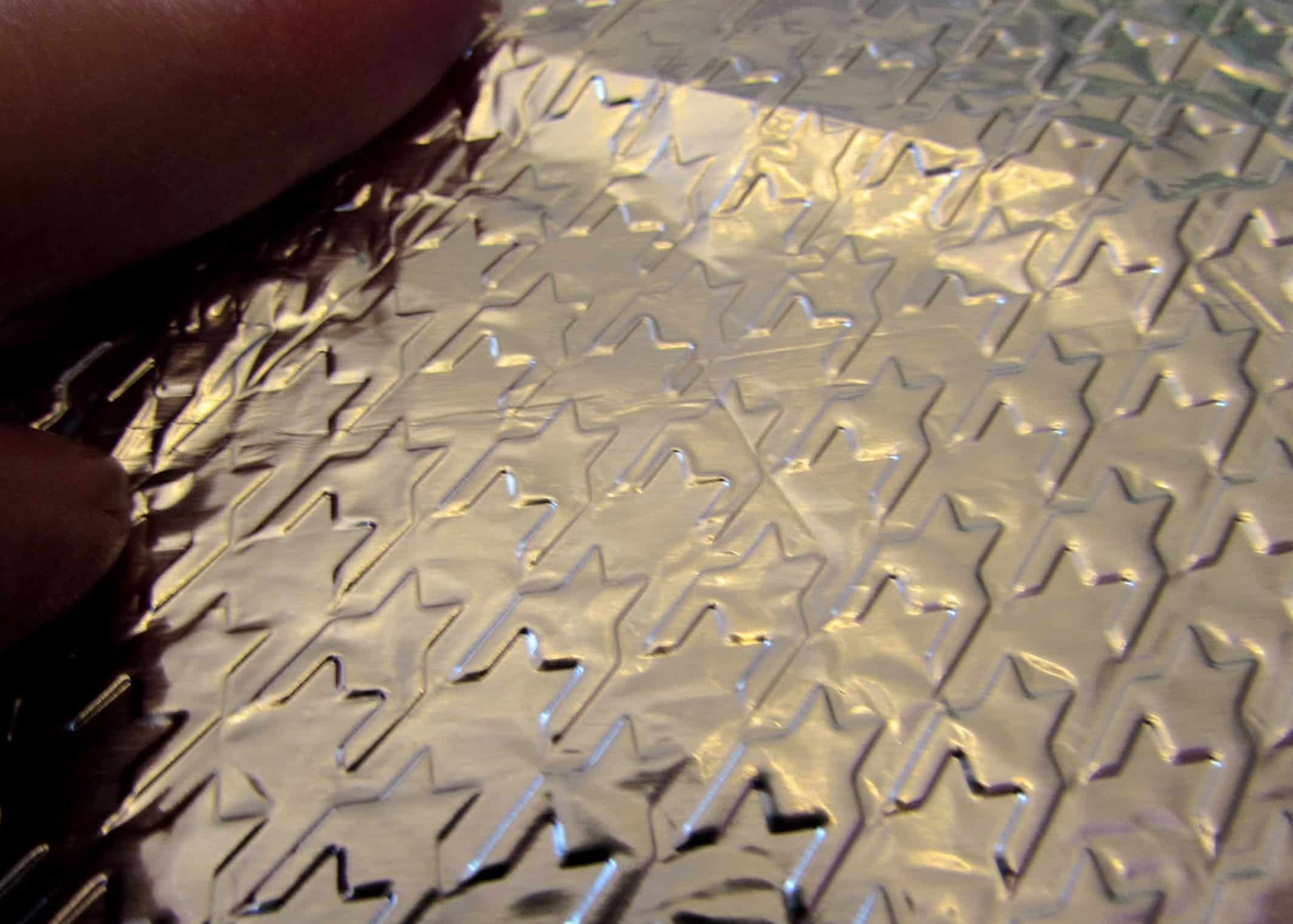

5) Aluminum tread/embossed plate, quenched and pre-stretched plate

6) PS baseplate, CTP baseplate, Signs, nameplate

7) Electrical products shell, engineering machinery plate

8) Aluminum reefer containers and special containers, etc.

9) Spinning, Auto, etc.

10) Printed aluminum sheet

11) Aluminum Sheet For Bus Skins

Look more at our website and our B2B website. welcome inquiry to us about 5083 Marine Aluminum Sheet