Marine Grade Aluminum Plate

At present, the market demand for marine aluminum plates is increasing year by year, and high-quality marine aluminum plates are even more competitive for customers at home and abroad. Tianjin Yikuo Aluminum C 5052 aluminum plate, 5083 aluminum plate, 5086 aluminum plate, 6061 aluminum plate, etc. are all hot-selling marine aluminum plates of Yikuo Aluminum.

- 5083. 5083 marine-grade aluminum is ideal for applications that need superlative corrosion resistance in hostile environments. 5083 is the strongest non-heat treatable aluminum alloy and maintains its strength even after welding.

- 5086. This alloy is highly conductive with superior corrosion resistance.

- 5454. The beneficial properties of 5454 include high strength, superior corrosion resistance, and good formability and weldability.

- 5456. 5456 is well-suited to the extrusion process. It is also amenable to forming operations like rolling and forging.

- 5754. Its superior resistance to corrosion makes 5754 very suitable for the marine industry and other industrial applications possessing corrosive operating environments. It is also suitable for flooring applications due to its high strength.

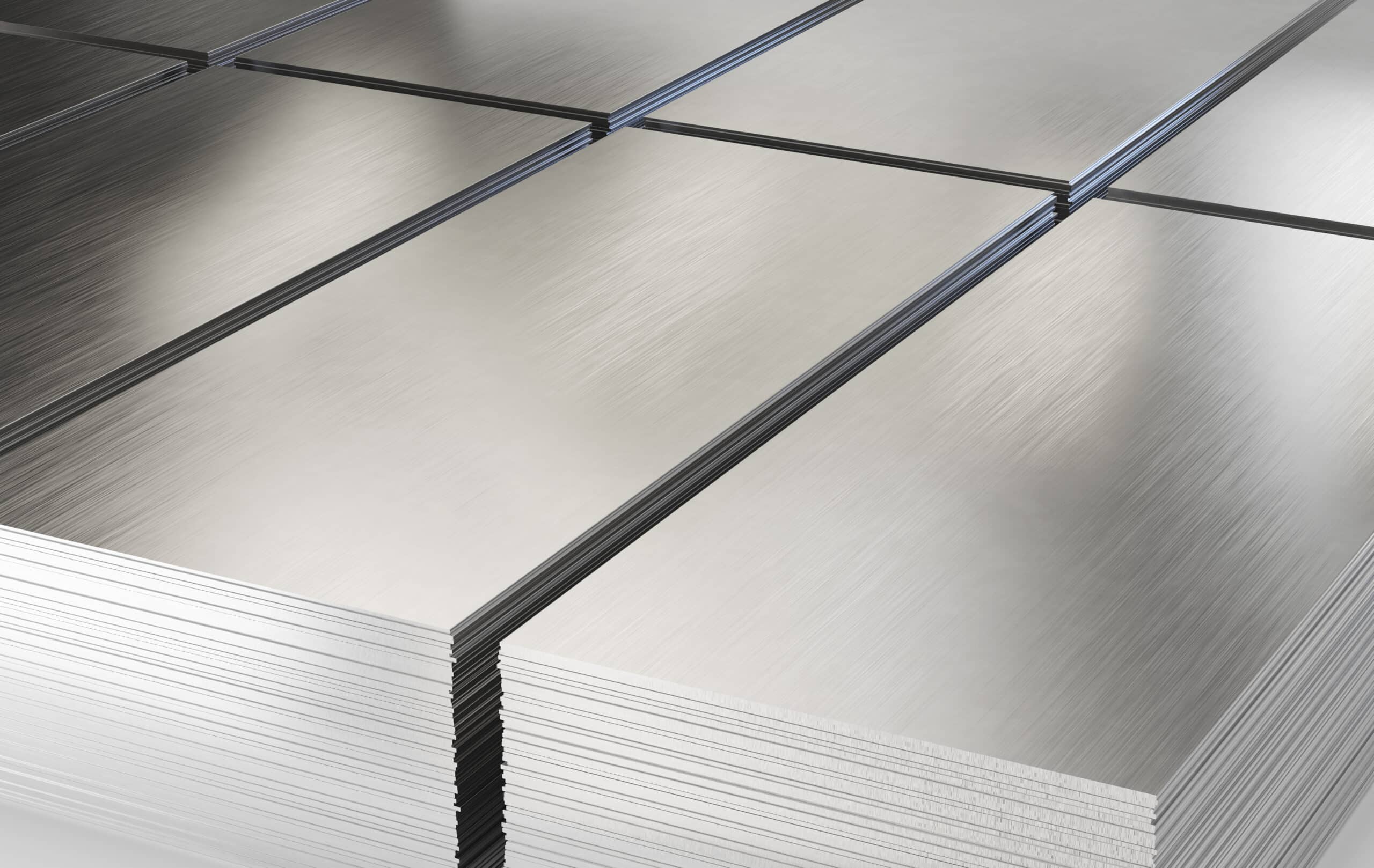

What’s the difference between Aluminum sheet 5083 H111 and Aluminum sheet 5083 H116? H111 VS H112 VS H116?

5083-H116 For products made of 5xxx series alloys with a magnesium content of 4% or more. These products have the required mechanical properties and resistance to spalling and corrosion.

5083-H111, full annealed products that have undergone a moderate amount of work-hardening, but can’t reach the hardness of the H11 condition.

5083-H321: This is suitable for processing aluminum materials with magnesium content greater than 4%, and the degree of work hardening in both hot and cold working is slightly less than that of H32. The technical parameters of H116 are demanding, with strict requirements for anti-corrosion properties and magnesium content; however, H321 has good performance stability.

Look more about our website and our B2B website.