3 series aluminum alloy is also known as aluminum magnesium alloy. Manganese content is 1-1.5%. It is a commonly used rust-proof aluminum alloy series. The strength of series 3 aluminum alloy is higher than pure aluminum alloy, although it can not be heat treated to enhance the performance, but after cold working (cold rolling) and annealing process has good plasticity. Because of its good corrosion resistance and welding performance, can be used in many industries, such as building decoration industry, electronic manufacturing, automobile manufacturing and so on.

Three series of aluminum alloy are commonly used in the main brand 3003 aluminum plate, 3005 aluminum plate, 3105 aluminum plate. Among them, 3003 aluminum alloy is the most used alloy.

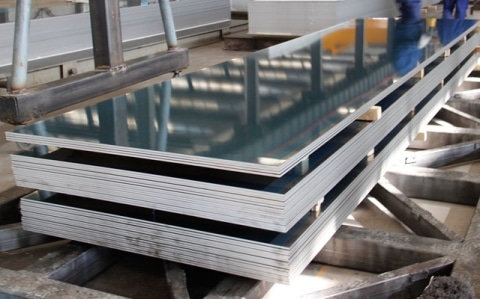

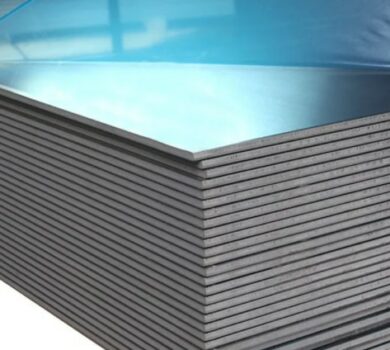

3003 aluminum plate is easy to process and has good rust resistance. It can be used for primary aluminum surface finishing, making various decorative materials such as indoor screen and wall panels. Used for more high-end color coated aluminum coil. It is produced in building materials industry, roof partition, mobile board room, etc., can also be used to manufacture air conditioners, refrigerators and other radiators, internal parts, etc. Some partition 5052 alloy used as truck fuel tank can also be replaced by 3003H24 aluminum plate to reduce the cost and not affect the use. Aluminum roofing plate can also be made by bending tile press, light and durable. Compared with 5052, 3003 is cheaper and has good welding performance.

3105 alloy can mainly be used to manufacture bottle caps and other stamping parts. In the TV manufacturing industry, 3104-O state plate is often used to make TV LCD backplane, forming oxidation after forming dense oxidation. The film is not only resistant to corrosion and oxidation, but also has good insulation, reducing the total weight of the finished product and ensuring good heat dissipation performance.