Perforated aluminum plate (also often called a punched aluminum plate) refers to a rectangular material with a uniform thickness that is made of pure aluminum or aluminum alloy material through shearing or sawing.

The perforated aluminum plate can be used in hotels, restaurants, theaters, broadcasting rooms, and other public buildings and medium and high-end civil buildings to improve the sound quality conditions, and can also be used in various workshops, air defense basements, etc.

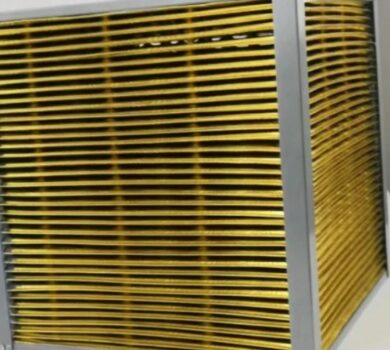

According to the hole specifications, the punching holes of perforated aluminum plate mainly include rectangular holes, square holes, diamond holes, round holes, long round holes, hexagonal holes, etc. Perforation rate refers to the percentage of the total area of perforation holes in the perforation area.

- The most common one is that the aperture is 6mm and the spacing is 15mm.

- According to the current mechanical equipment, the highest perforation rate can reach about 65%, and the size of the perforated plate is required to be within the range of 1500*3000. If it exceeds this range, the perforation needs to be positioned twice.

- The higher the perforation rate of the perforated aluminum plate, the greater the impact on the flatness of the formed aluminum plate, and the inspection standard is lower than the corresponding regulations of the normal aluminum plate.

For more information, please visit: yk-al.com