Trend of the Solar Cells

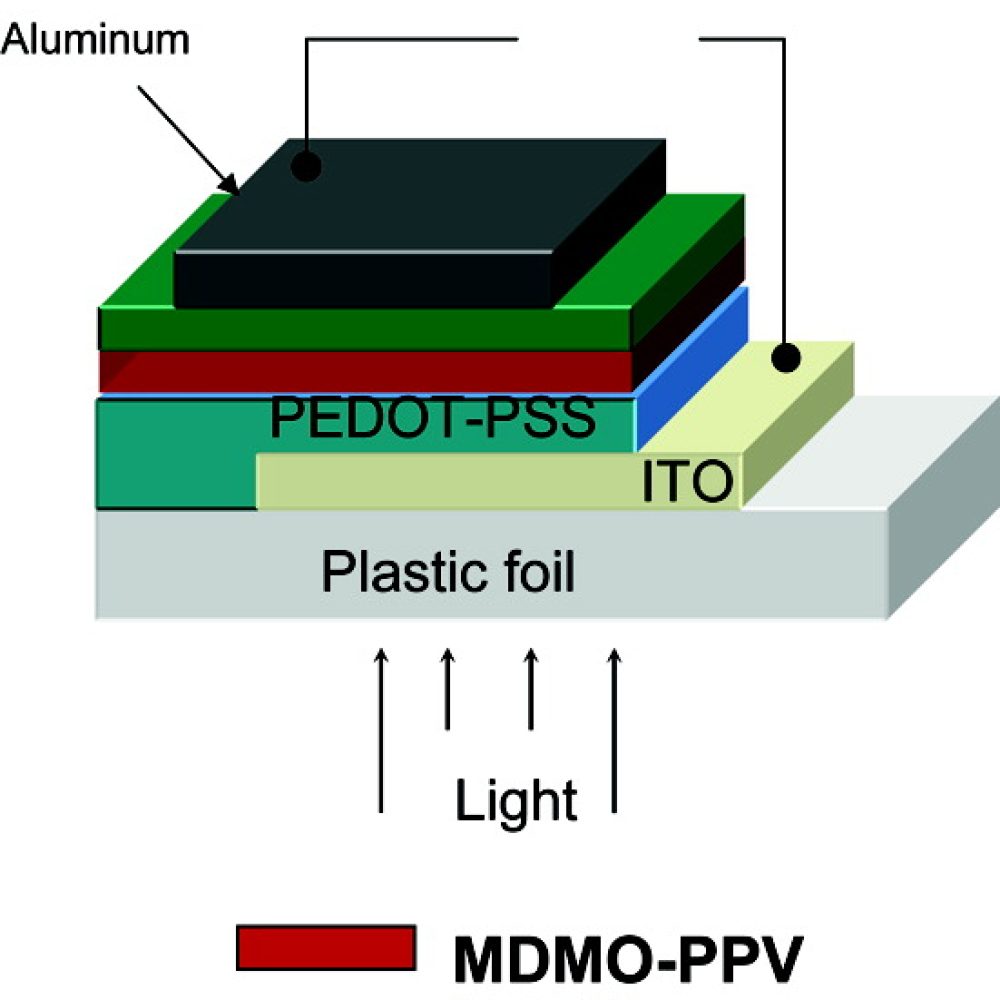

In order to save energy and reduce emissions, solar photovoltaic panels are everywhere, on rooftops, on factory floors, and beside the sidewalk in communities. Governments are actively promoting this renewable energy. Germany plans to switch completely to green electricity by 2035, so it has made more stringent rules for installing solar equipment in new buildings. Germany’s Renewable Energy Law stipulates that the total national photovoltaic capacity should reach 215kMW in 2030. According to the PV strategic plan of the German Federal Ministry of Economic Affairs, the new optical installed capacity must be tripled from 7kMW in 2022 to 22kMW per year. To install so many solar photovoltaic panels, there must be enough space, so scientists research new organic solar panels that can be installed anywhere. This new type of solar panel is thin and flexible, and it is not made of silicon, but of hydrocarbons.

The Main Barrier of the Producing Solar Cells

The rigid, curved roof, body and aircraft wing static characteristics of traditional solar cells are not suitable for installation until now, and the new flexible solar panels can be used not only for these occasions, but also on glass curtain walls and Windows. At present, the preparation cost of organic solar panels is not cheap, therefore, it is imperative to reduce the production cost, once the production cost is reduced to a competitive level, this technology will be unprecedented rapid development.

Aluminum Materials Will Help Solving the Barrier

Dresden University of Technology in Germany is the birthplace and center of research and development of organic solar cells. The research team led by Professor Leo has been engaged in this research since the 1990s, and about 30 companies and dozens of research institutions from around the world are also carrying out relevant research. In 2006, Professor Leow, together with five other scientists from Dresden University and Ulm University, founded the company Heliatek, which has been mass-producing organic solar cells since 2019 and has become a leader in this field. The company has major customers around the world, such as Germany’s E.ON Energy Group and South Korea’s Samsung Group, as well as customers from France, Spain, the United Kingdom, Singapore and Japan, with particularly strong demand in Southeast Asia. The frame of the organic solar panel is all processed with 6063 aluminum alloy extruded profiles, and the battery shell is mainly prepared with aluminum foil. 6063 alloy composition (mass %) : Si (0.20 ~ 0.6), Fe≤0.35, Cu≤0.10, Mn≤0.10, Mg (0.45 ~ 0.9), Cr≤0.10, Zn≤0.10, Ti≤0.01, other impurities ≤0.05, total ≤0.15, the rest Al. Although the tensile strength of 6063 alloy is not high, only 90N/mm2, it can fully meet the design requirements, the elongation exceeds 20%, and has good forming and processing performance, which is the largest aluminum alloy at present.