- Aluminium Coil

- Aluminum Profile, Aluminum Extrusion

- Aluminum Strip for Cap/Lid/Sealing

- Blogs

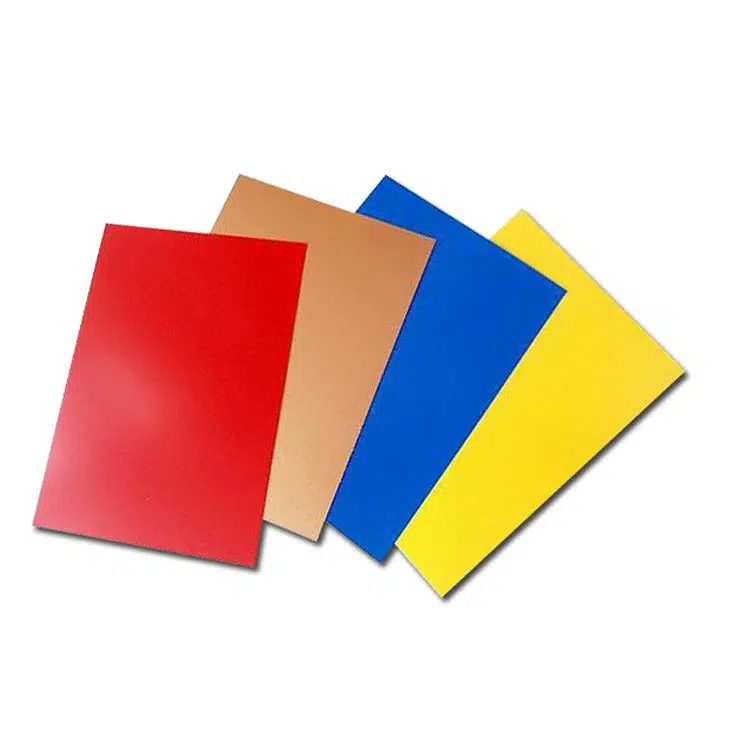

- Color Coated Aluminum Coil

- Contact Us

- Logistics case study

- Products overview

- Recruit

- Team

- Thank you for contacting us

- Thanks for contacting us

- Tianjin Yikuo Aluminum Foil

- Tracking report will be sent shortly

- Yk Aluminum

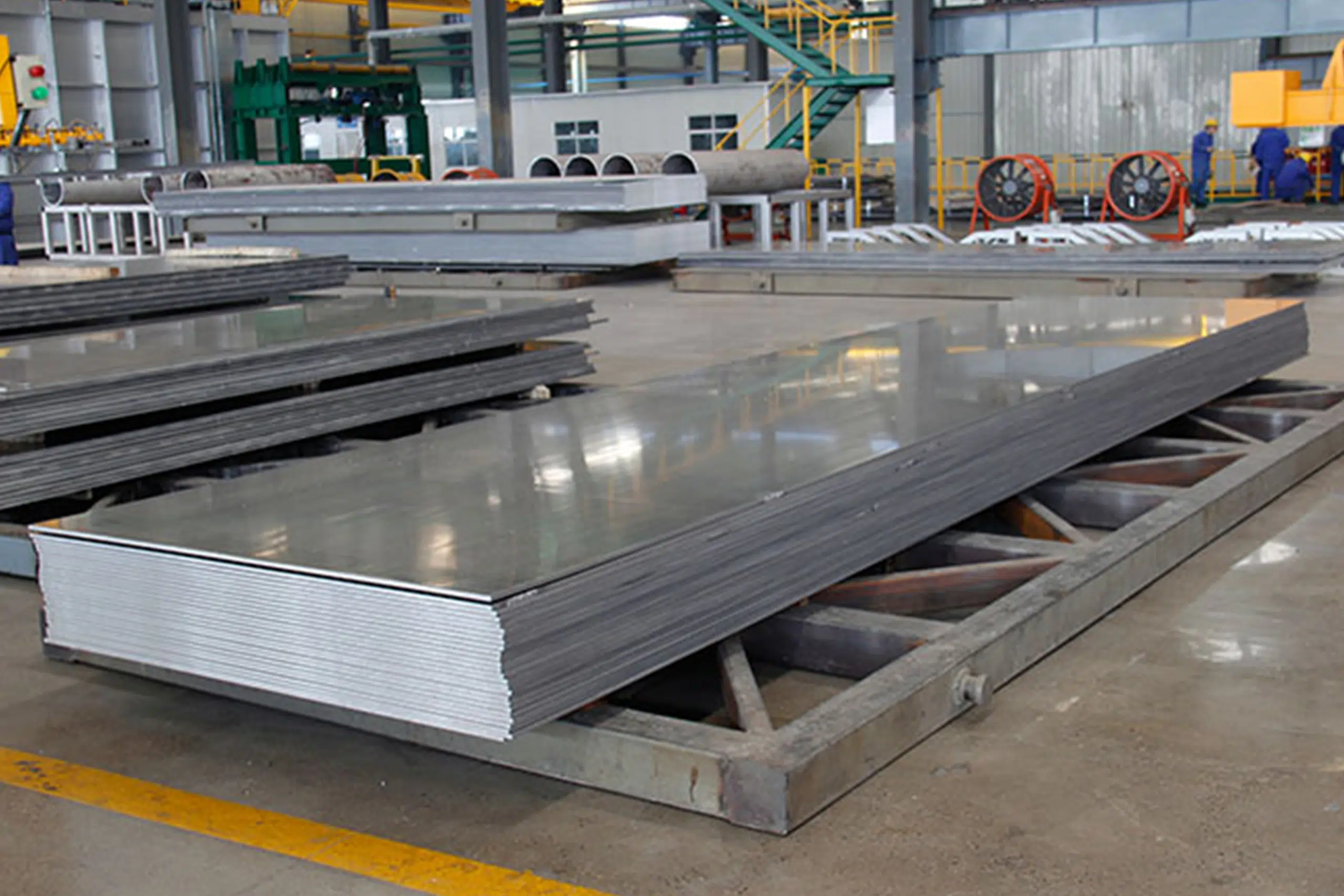

- YK Aluminum Sheet Plate

- YK Aluminum Stock

- YK Aluminum Strip

- YK Aviation Aluminum

- YK Factory

- YK Household Aluminum Foil

- YK Marine Grade Aluminum

Main Menu