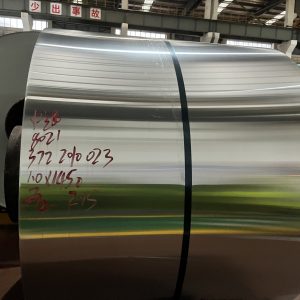

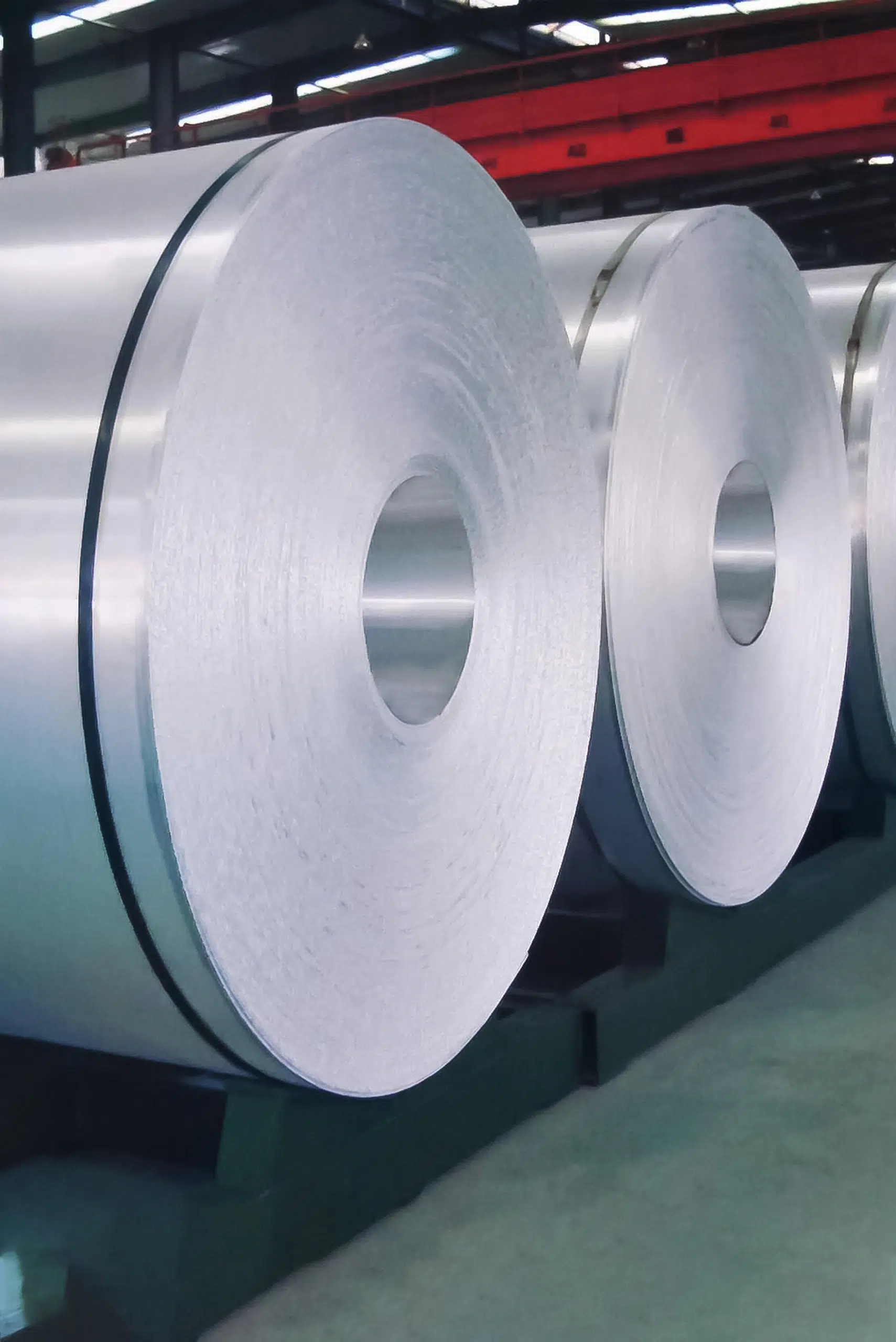

1050 Aluminum Coil

We sincerely appreciate your interest in our 1050 Aluminum Coil for your projects within the packaging, construction, and electronics industries. Our product boasts several distinctive qualities that cater to a wide range of requirements.

One of the standout features of our 1050 Aluminum Coil is its exceptional resistance to corrosion, making it the ideal choice for environments where corrosion resistance is crucial, such as in construction and electronics applications. Additionally, it is conductive and exhibits strong thermal conductivity, rendering it suitable for various electrical and thermal applications. Its ease of processing offers versatility in manufacturing, ensuring it can be customized to meet your unique specifications.

Please be aware that high-temperature conditions are not suitable for this material. However, we offer a MOQ-friendly strategy, enabling you to order the quantity that best suits your needs, promoting flexibility and cost-effectiveness in your projects.

We are committed to provide the designs you want. If you have any questions or would like to discuss how our 1050 Aluminum Coil can further enhance your unique applications, please do not hesitate to contact us. Your satisfaction is our happiness and we eagerly anticipate the opportunity to collaborate with you.

look more about our B2B website and our product