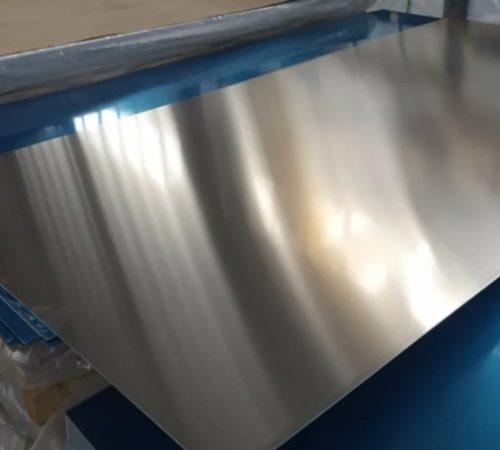

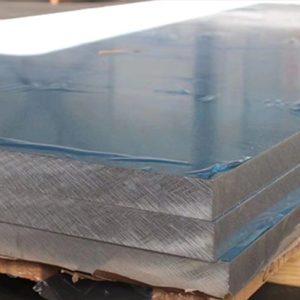

A versatile material renowned for its high strength, corrosion resistance, and thermal conductivity, brazing aluminum sheets have gained popularity in driving innovation within the automotive industry. Our sheets find application in a wide range of automotive components, including heat exchangers, composite fins, composite plates, composite strips, tube blanks, and various weld tubes.

Our brazing aluminum sheets serve as a shield against the corrosive effects of the environment. They enable innovative design solutions that optimize heat transfer and durability, ultimately enhancing thermal performance and reducing energy consumption.

It's important to note that brazing processes involve the use of fluxes, which may contain toxic components. Therefore, safe handling and disposal practices are essential. While brazing aluminum sheets offer numerous benefits, it's worth mentioning that they may produce joints of lower strength compared to welding and may not be suitable for high-temperature applications, unlike welding. However, our sheets have already proven their worth. They provide cost-effective solutions, and our rigorous quality assurance processes ensure they meet and exceed industry standards.

Reach out to us and reward yourself with easy processing and after-sales support. Your project demands high-quality materials that offer durability and reliability. At YK Aluminum, we ensure worry-free transactions, from inquiry to application.