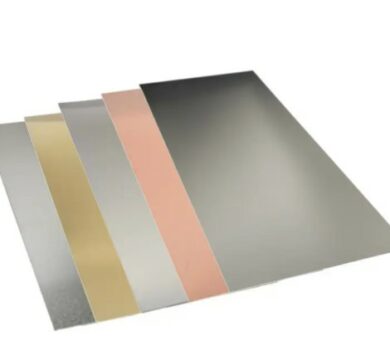

Aluminum sheets can be used in various industries, such as construction, automotive, and architectural design due to their lightweight, durable, and corrosion-resistant properties. The first question that comes to your mind when planning to work on a project is, “How much does a 4×8 sheet of aluminum cost?”. In this article, we will help you explore the cost and the significant factors affecting the price of this sheet, helping you make an informed decision for your next project.

What Is a 4×8 Sheet of Aluminum Size?

This particular size finds widespread applications in construction, automotive, and interior design projects, primarily because of its versatility and ease of transportation. It strikes an excellent balance between ease of handling and functionality. So, whether you’re considering the construction of wall panels and cabinets, or planning on a DIY project, the 4×8 aluminum sheet is a choice worth considering.

Factors Affecting the 4×8 Aluminum Sheet Cost

Custom Cuts

The cutting services offered by many manufacturers influenced the cost. When you purchase the standard 4×8 sheet of aluminum, you buy a sheet with fixed dimensions of 4 feet in width and 8 feet in length and you will get a fixed price for this product. However, not all projects require the full size of a 4×8 sheet, and this is how a supplier often charges for custom cut services, which can add to the overall cost, because this requires additional labor and the use of specialized equipment for precise sizing. The more custom cuts you require, the higher the cost.

Market Price

The market price of aluminum is also affected by fluctuations based on various factors such as supply and demand, global economic conditions, and trade policies. When the market price of aluminum increases, the cost of a 4×8 aluminum sheet also increases, and vice versa. This can affect the availability of aluminum sheets. During periods of high demand or supply shortages, prices can spike. In highly competitive markets, suppliers may offer more competitive prices to attract customers.

Additional Costs

Shipping Cost and Handling Fee: The distance needed to travel and the choice of shipping method can influence the costs. The longer distance and shipping options such as ground, air, or sea freight typically result in higher shipping costs. Various pricing structures may differ depending on shipping providers. Larger orders may ship in bulk, which can be more cost-effective per unit. It’s important to compare the shipping rates and choose a provider that offers a balance of cost and service.

Sales Tax: This varies by location. Tax rates are added to the total cost of your purchase depending on your state or region.

Rush Orders: this service usually incurs extra service charges if you are requesting expedited processing or delivery.

How to Budget Effectively

When planning to start a project, calculate an estimate based on your specific requirements. Learn to ask and compare quotes from different suppliers to find the best deal. Familiarize yourself with the shipping cost and sales tax regulations in your area and explore any potential exemptions that may apply to your situation. And lastly, when possible, negotiate with your aluminum sheet supplier to include or reduce extra service costs as part of your overall agreement.

Conclusions

Staying informed and adapting your procurement strategies to market conditions can help you manage costs effectively. By accounting for these factors affecting the 4×8 sheet of aluminum cost, you can accurately assess the total cost of acquiring this sheet. This will help you make an informed decision and avoid unexpected expenses.