How are aluminum sheets made?

YK aluminum sheets, which are versatile materials used in a variety of industries, are manufactured in a complex process to reach the desired thickness, dimensions, and qualities. These comprehensive ideas take you on a step-by-step journey from raw aluminum ingot to polished aluminum sheet ready for usage.

Choosing an Aluminum Alloy:

It all starts with the careful selection of an aluminum alloy that is appropriate for the intended use. Aluminum alloys are available in a variety of grades, each with unique qualities such as strength, corrosion resistance, and formability.

Production of Aluminum Ingots:

The initial step in the production of YK aluminum sheets is the creation of aluminum ingots. This is generally accomplished by an electrolytic reduction method in which aluminum oxide is dissolved in molten cryolite and then electrolyzed to give aluminum metal. The resulting aluminum is cast into massive, rectangular shapes called billets or slabs.

Preheating:

The billets are warmed in a furnace to make them more pliable and lessen the possibility of cracking during rolling.

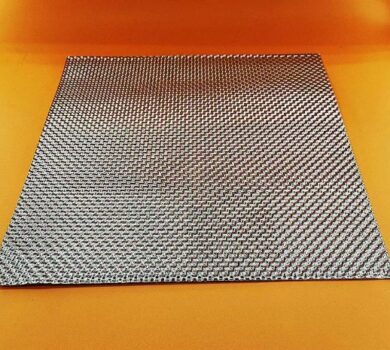

Rolling on a Hot Plate:

Hot rolling, a sequence of precisely planned procedures that change the billet into a thin sheet, is at the heart of the aluminum sheet manufacturing process.

Hot rolling is accomplished through several passes through rolling mills outfitted with pairs of rollers. Each pass thins the sheet while increasing its length and width.

Roughing passes begin the process by quickly lowering thickness, whereas finishing passes refine thickness and surface finish.

During hot rolling, the metal remains at a high temperature, allowing it to deform without shattering.

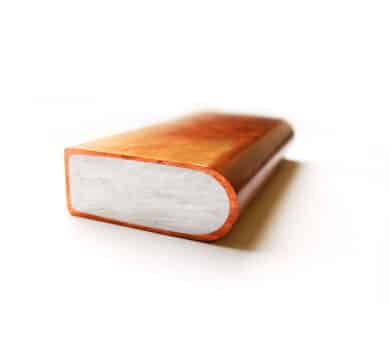

Coil cooling and coiling:

The aluminum sheet is commonly cooled using air or water sprays after each run through the rolling machine to maintain its characteristics and dimensions.

After that, the sheet is carefully wound into enormous spools for further processing or storage.

Optional cold rolling:

Hot-rolled aluminum sheets can be cold-rolled for applications requiring even tighter thickness tolerances and a better surface finish.

Cold rolling is done at or near room temperature and entails passing the sheet through several sets of rollers with smaller intervals between them.

Annealing is optional.

Annealing is a heat treatment procedure that can occur after either hot or cold rolling. YK Aluminum’s objective is to relieve internal tensions, improve ductility, and improve the mechanical properties of the material.

During this process, the aluminum sheet is heated to a specified temperature and then progressively cooled to room temperature.

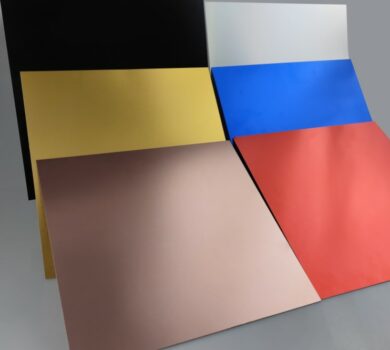

Surface Finishing:

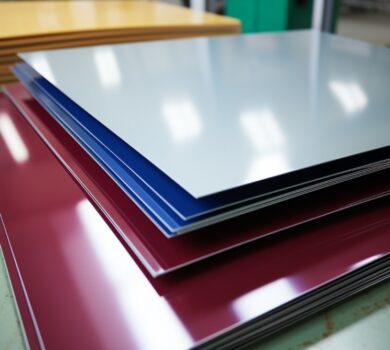

Depending on the application, the aluminum sheet may be subjected to a variety of surface treatments, including:

Cleaning is the process of removing pollutants or residues from a surface.

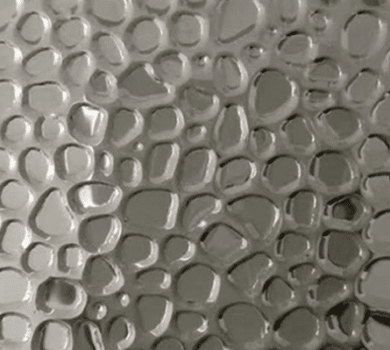

To achieve a smoother, more reflective surface finish, polishing is used.

Anodizing is an electrolytic technique that generates a protective oxide layer on the surface of a metal to improve corrosion resistance and aesthetics.

Coating: the application of protective coatings to improve environmental resilience

Packaging and cutting:

When the aluminum sheet has reached the desired thickness and surface polish, it is sheared or sawed into standard or custom sizes.

The YK aluminum sheets are carefully wrapped, labeled, and ready for dispatch to consumers all over the world.

Every stage of the manufacturing process is meticulously controlled to guarantee that the produced aluminum sheets meet high standards and customer-specific specifications. These aluminum sheets are used in a wide range of applications, from aerospace and automotive components to building materials and packaging, demonstrating the material’s adaptability and dependability.