Aluminum sheets and aluminum plates are two popular options when selecting the proper form and alloy for aluminum materials. Each possessed unique characteristics. Let’s take a closer look at their differences and the comparison between two widely used alloys, the 5052 and 6061.

Difference Between AluminumSheet and Aluminum Plate

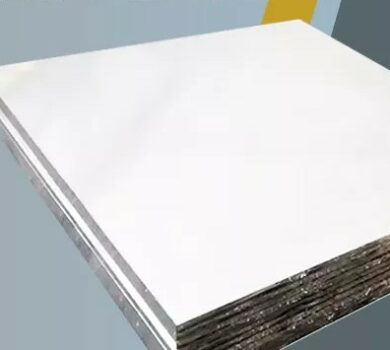

Aluminum Sheet

This is a flat piece of aluminum with various thicknesses that are typically 6mm (¼ inch) or less and often used in applications where weights and formability are necessary, such as automotive, aerospace, construction, and packaging for panels, decorative trim, and lightweight structural components. They are easily cut, bent, and formed using fabrication techniques due to their thin nature, making them suitable for welding and other joining methods. They are considered with good strength but are not as robust as plates.

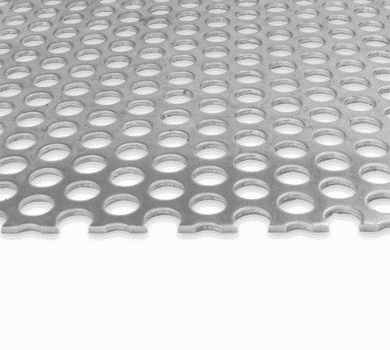

Aluminum Plate

They are thicker than sheets, at greater than 6mm of thickness. Plates are used in heavy-duty structures in industries like marine, transportation, and industrial manufacturing, where strength, durability, and load-bearing capacity are essential. They require specialized tools and equipment for cutting, shaping, or machining. Due to their thickness, aluminum plates are heavier and are chosen when strength is needed, even if it comes at the cost of added weight.

The choice between the two depends on the requirements of your project, considering factors like strength, durability, and intended use.

5052 Aluminum Sheet vs. 6061 Aluminum Sheet

Now, let’s compare the 5052 aluminum sheet and the 6061 aluminum sheet, the two widely used aluminum sheets, and their distinct properties and suitability for different applications.

5052 Aluminum Sheet

Corrosion Resistance: It offers corrosion resistance attributes ideal for marine and chemical applications.

Strength: Not as strong as the 6061 aluminum sheet, but offers good strength and is suitable for general-purpose projects.

Formability: This aluminum sheet is highly formable and can be easily bent, shaped, and welded.

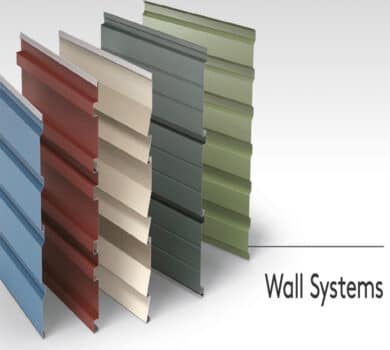

Applications: Commonly used in boat hulls, fuel tanks, automotive components, panels and decorative elements, and architectural trim.

6061 Aluminum Sheet

Strength: This is known for its undeniable strength and is heat-treatable.

Weldability: Has good weldability, but with required special welding considerations.

Machinability: The 6061 aluminum sheet is easily machinable and can be precision-engineered for complex parts.

Applications: Ideal for aerospace components, automotive parts, bicycle frames, structural components, and machine parts and assemblies.

Conclusion

In summary, both aluminum sheets and aluminum plates are versatile materials that offer unique advantages based on their thickness and alloys. The 5052 aluminum sheet is ideal for applications that require both corrosion resistance and formability. While the 6061 aluminum sheet excels in high-strength and machinability applications.

Just remember, that selecting between two different aluminum sheets will depend on the requirements of your project to ensure the success and longevity of your projects. You have to carefully understand their unique characteristics before making a decision, like strength, durability, and intended use.