Yk Aluminum is renowned for its exceptional qualities like lightweight, corrosion resistance, and adaptability. Among its various uses, bending and shaping aluminum sheets is essential for producing a variety of things, including consumer goods, architectural components, and automotive components. We go into the art of bending and shaping aluminum sheets in this thorough guide, going through the methods, uses, and what you can count on from our services.

Aluminum Sheet Bending Techniques

Aluminum sheets can be bent to create certain angles or curves without the material being fractured. In sectors including construction, aerospace, and automobile manufacture, this technique is essential. Taking a deeper look at what involves bending metal sheets

Types of bending:

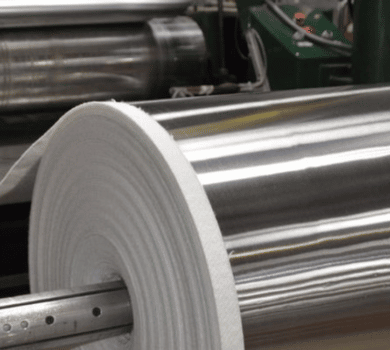

Press brake, roll, and rotary draw bending are only a few of the methods used to bend aluminum sheets. Depending on the intended shape and use, different methods are employed because each one has its own advantages.

Precision and tolerance:

When bending aluminum sheets, precision is crucial. The quality of the finished product might be impacted by even slight variations. The greatest level of quality and exact tolerance control are guaranteed by our cutting-edge machinery and knowledgeable personnel.

Material selection:

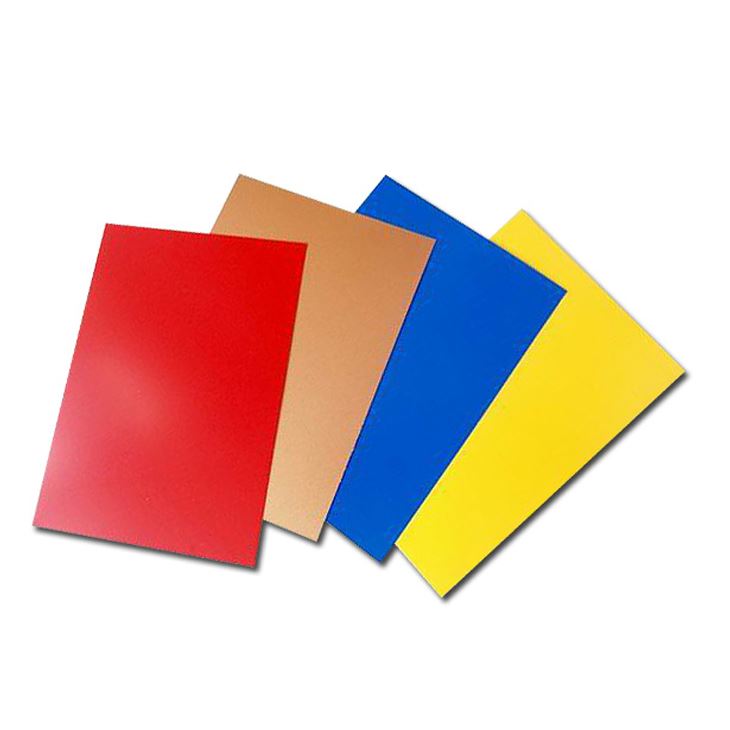

There are numerous alloys of aluminum sheets, each with unique features. The selection of an alloy is influenced by properties including strength, corrosion resistance, and formability. Choose the best aluminum alloy for your project with the aid of our Yk specialists.

Unleashing Creativity in Shape-Making Aluminum Sheets

A wider range of techniques are used for shaping aluminum sheets, enabling the construction of elaborate patterns and complex shapes. Industries including architecture, the arts, and consumer electronics all rely on this process. What you should know about shaping aluminum sheets is as follows:

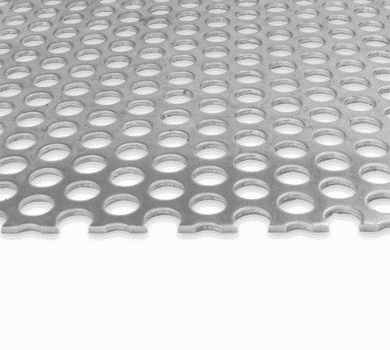

Aluminum sheets are very adaptable and may be shaped using a wide range of techniques, such as hydroforming, stamping, and CNC machining. The ability to produce a variety of goods, from decorative facades to aeronautical components, is made possible by this adaptability.

Also, the ability to shape aluminum sheets gives designers unmatched flexibility. Pushing the limits of inventiveness, complex geometries, elaborate patterns, and organic shapes can all be produced.

Aluminum sheets can be formed to obtain a variety of surface treatments, including brushed, polished, textured, and coated, to meet a variety of aesthetic and practical needs.

What We Provide

We are dedicated to providing aluminum sheet bending and shaping services that are of the highest caliber at YiKuo Aluminum. What distinguishes us is this:

Knowledge:

Our team of skilled specialists has a thorough understanding of aluminum alloys and cutting-edge fabrication methods.

Modern machinery:

It is one of the investments we make to ensure accuracy and efficiency in every project.

Custom Solutions:

We adapt our services to match your unique needs, whether you need simple, pre-made shapes or intricate, custom designs.

Quality Control:

Strict quality assurance procedures ensure that our products adhere to the strictest industry requirements.

Delivery on time:

We are aware of the significance of fulfilling deadlines. Our effective process guarantees that projects are finished on time.

In conclusion, bending and shaping aluminum sheets is a crucial procedure that opens up a vast array of design options and practical uses. We at Yk Aluminum provide complete solutions to make your projects using aluminum sheets a reality. To find out how we can assist you with bending and shaping aluminum sheets, get in touch with us right now.