Stamped aluminum sheets are one of the several uses and sectors that aluminum has found its way into. Yk aluminum is a fantastic material that comes in many different forms. These sheets are made using a technique known as stamping, in which a metal sheet is squeezed between dies to produce a variety of forms and patterns. Stamped aluminum sheets are a common choice in sectors like automotive, aerospace, construction, and design since they provide a variety of advantages. We’ll look at the features and benefits of stamped aluminum sheets in this post.

Lightweight and robust:

The small weight of stamped aluminum sheets is one of their main benefits. Yk aluminum is a great material to use when weight reduction is important because of its low density.

Stamped aluminum sheets are exceptionally strong despite being lightweight. Because they are corrosion-resistant, they will last even in adverse environmental circumstances. In fields like aerospace and automotive, where losing weight can increase performance and fuel efficiency, this combination of lightness and toughness is very useful.

Designs with options:

Aluminum sheets that have been stamped give countless design options. With extreme precision, complicated and complex shapes can be made using the stamping technique. They are perfect for both ornamental and practical purposes because of their versatility. Stamped aluminum sheets can provide the desired aesthetics and performance, whether you need elaborate designs for automotive parts, perforated patterns for architectural use, or custom logos for branding.

Environmental advantages

A very sustainable material is aluminum. It is completely recyclable and retains all of its original qualities. Stamped aluminum sheets are an environmentally favorable option because of their potential to be recycled. Utilizing aluminum sheets in your projects helps to promote sustainability and lessen the impact on the environment.

Outstanding thermal conductivity:

Excellent thermal conductivity can be found in stamped aluminum sheets. Applications where heat dissipation is essential, such as heat sinks for electronics or parts of HVAC systems, benefit greatly from this characteristic. Aluminum’s strong thermal conductivity ensures effective heat transfer, assisting in the maintenance of ideal operating temperatures.

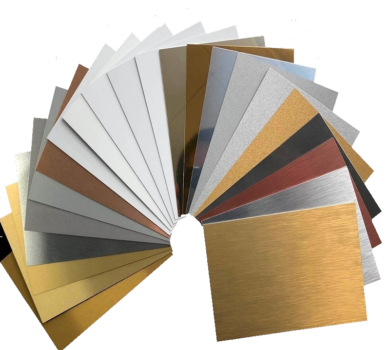

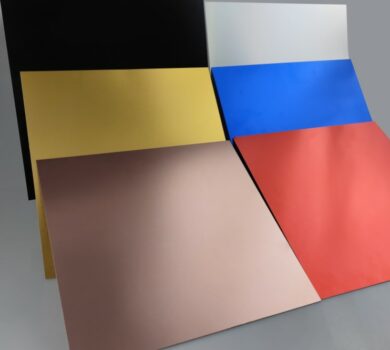

Variety of finishes

Polished, anodized, and painted finishes are all available for stamped aluminum sheets. In addition to improving aesthetics, these coatings offer more protection against corrosion and wear. Due to the variety of finishes available, you can select the ideal appearance and performance attributes for your unique application.

Finally, stamped aluminum sheets are a flexible and dependable option for a range of businesses and uses. They are a favorite choice for designers, engineers, and manufacturers because of their versatility, environmental advantages, lightweight yet robust nature, thermal conductivity, and variety of finishes. Stamped aluminum sheets provide the strength and flexibility you need to finish your projects, whether you’re making high-tech electronics, architectural elements, or automotive components. Stamped aluminum sheets will continue to be essential in influencing the future of numerous sectors as technology develops and design standards change.