The joining of metal sheets in a variety of industries, such as the automobile, aerospace, and electronics, is frequently accomplished by spot welding. Due to the special characteristics of aluminum, there are particular difficulties and considerations while spot welding aluminum sheets. You will find a thorough explanation of spot welding aluminum sheets on this page.

Knowledge of Aluminum

Aluminum is a non-ferrous, lightweight metal renowned for its superior conductivity and resistance to corrosion. However, due to its low melting point and strong heat conductivity, it presents certain difficulties when it comes to welding. Knowing these qualities is essential for effective spot welding.

Tools and Materials

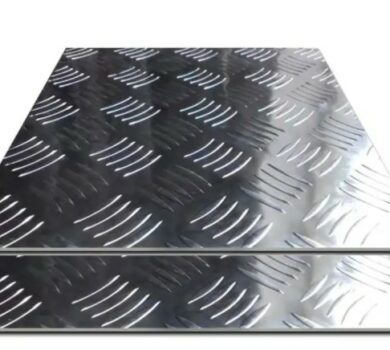

You’ll need a spot welding machine with the controls you need to change the current, time, and pressure settings. Check to see if it can handle metal. Use copper-chromium-zirconium alloy electrodes because these materials can survive the intense heat produced during the process and prevent aluminum from becoming contaminated. Ensure that the Yk aluminum sheets you plan to weld are spot-weldable (often between 0.5 mm and 3 mm thick), clean, and free of impurities.

Preparation

Clean the Aluminum’s surface quickly produces aluminum oxide, which makes welding difficult. To remove any oxide layers, clean the surfaces with a wire brush, abrasive pad, or chemical cleaning before welding.

For consistent contact to be maintained between the sheets while welding, proper clamping is crucial. To firmly fix the aluminum oxide sheets in place, use fixtures or clamps that were expressly intended for the job.

Modifiers and Settings

Due to its great heat conductivity, Yk aluminum requires higher welding currents than other metals. Try out several current settings to determine the best one for your particular aluminum sheets. Usually, current levels are in the 6,000–12,000 ampere range.

The thickness of the sheet and the characteristics of the material affect the welding time. Start with lesser periods and raise them gradually until you get a good weld. Welding times for thin aluminum sheets can be as little as a few milliseconds.

For optimal electrode-to-workpiece contact, sufficient pressure is essential. According to the capability of your machine and the thickness of the material, adjust the pressure settings.

The Method of Spot Welding

To position the electrodes, press the copper electrodes firmly on the aluminum sheets.

In applying the pressure, turn on the welding equipment and press down on the electrodes as needed. Start the welding procedure by allowing the current to flow through the aluminum sheets for the allotted amount of time. Depending on the application, either let the welded area cool naturally or hasten the process with forced air or water cooling.

Safety Measures

When spot welding aluminum sheets, safety comes first:

Wear the proper personal protection equipment (PPE), such as heat-resistant clothes, welding gloves, and safety eyewear. To disperse fumes and avoid exposure to dangerous gases, make sure the welding area is well ventilated. For machine operation and maintenance, adhere to the manufacturer’s instructions.

Conclusion

Aluminum sheet spot welding can be a difficult but rewarding process. You may produce sturdy and dependable welds in a variety of applications by comprehending the aluminum sheet sizes and their unique characteristics, employing the appropriate tools and materials, and carefully managing the welding settings. Always put safety first, and for best outcomes, practice and perfect your spot welding procedures.