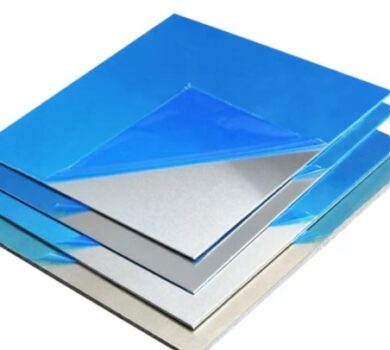

When creating a DIY or professional fabrication, achieving the right finish requires the right techniques and tools. Sanding aluminum sheets is a craft with a perfect combination of precision and finesse when processed properly. Careful execution of the procedure will help you transform raw aluminum into a polished masterpiece.

In this article, we will help you understand the right methods, tips, and tricks to achieve top-notch sanding aluminum sheets.

Methods for Sanding Aluminum Sheets

Sanding Preparation

Safety First

Creating a suitable work environment is important for safety and achieving the desired results. Proper ventilation, surface cleaning, and workspace organization ensure a smooth sanding process. Always wear safety glasses or goggles to protect your eyes from debris. Use a dust mask or respirator to avoid inhaling aluminum dust. Sanding aluminum produces dust and fumes, so work in a well-ventilated space and regularly remove dust and debris to maintain a safe environment. Secure the aluminum sheet before sanding and use the right grit to remove imperfections. Taking a short break is necessary to rest your hands and avoid overexertion. Clean up thoroughly. Dispose of all the used sandpaper and clean the work area and tools to prevent contamination and hazards.

Tools and Equipment Needed

Having the right equipment is also essential for a successful sanding project. Here’s a list of the tools and equipment you’ll need:

- Sandpaper

- Hand Sanding Blocks

- Backing Pad (For Power Sander)

- Abrasive Pads (Scotch Brite or Similar)

- Solvent or Degreaser

- Ruler or Templates

- Cleaning Supplies

You can effectively and safely sand aluminum sheets by following these tools, equipment, and safety practices to achieve your desired finish.

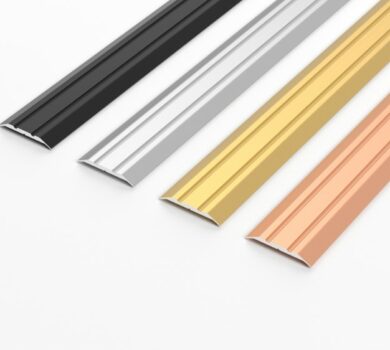

Choosing the Right Grit

Choosing the right grit determines the texture and finish of the final surface. The choice depends on your project goals. If you want a smooth and polished surface, you’ll need finer grits. For a textured or matte finish, coarser grits are suitable. If the surface is rough or damaged, you may begin with a lower grit, such as 80 or 120. As you work, gradually move to finer grits like 220, 320, 400, 600, or higher. This will help you refine the surface and remove scratches left by coarser grits.

Perform a test in a small area if unsure which grit to start with. Consider seeking advice from professionals if you’re working on a specialized project or with a particular aluminum alloy.

Be patient, take time, and experiment if needed to achieve the desired result when sanding aluminum sheets.

Step-by-Step Process of Sanding Aluminum Sheet

Preparing the Surface

Begin by cleaning the aluminum sheet to remove any dirt, grease, or contaminants. Use a degreaser and a clean cloth to ensure a clean working surface.

Initial Sanding

Hold the sandpaper or sanding block at a slight angle (about 10 to 15 degrees) to the surface. Avoid pressing too hard, to prevent uneven surfaces and scratches. Covering the entire surface by sanding in one direction, moving back and forth evenly.

Progressive Sanding

Use long and straight strokes for dry sanding. While for wet sanding, you can use circular or figure-eight motions. Maintain a consistent pattern to achieve an even finish and progress to finer grits as you work.

Finishing Touches

Clean the aluminum sheet thoroughly with clean cloths and inspect the surface for any imperfections or areas that may need further attention. You can use aluminum polish or a polishing compound if you want to achieve a high gloss. Apply the polish to a clean, soft cloth or polishing wheel and buff in circular motions. Wipe away any excess polish with a clean cloth.

Anodizing is an electrochemical process that can be used to enhance the appearance and corrosion resistance of aluminum. It creates a protective oxide layer on the surface. They come in various colors and finishes.

Tips and Tricks

Common Sanding Mistakes

Here are some common mistakes to avoid:

- Using the wrong grit

- Applying uneven pressure

- Sanding in the wrong direction

- Neglecting safety precautions

- Rushing the process

- Using worn sandpaper

Avoiding the above-mentioned sanding mistakes will help you achieve a smooth, flawless finish on your aluminum sheet and ensure that your project turns out as intended.

Conclusion

Mastering the right process of sanding aluminum sheets is essential whether you are restoring the shine of an old aluminum panel or preparing a surface for a new project. With the right knowledge, techniques, and tools, you can transform raw aluminum sheets into refined works of art.