Researchers at the Pacific Northwest National Laboratory (PNNL) have developed a new process that could halve the energy required to make high-performance aluminum alloys.

Shear assisted machining and Extrusion (Shape) technology can eliminate the heat treatment step in the production process, leading to significant energy savings and reduced emissions, according to scientists.

ShAPE is defined as a green, economical manufacturing method that can be used in a wide range of high performance aluminum alloys for automotive applications.

In a paper published in the journal Materials and Design, the researchers explain that conventional metal production uses heat to melt individual metals and alloying elements, such as aluminum, copper or magnesium, together to create alloys that are lighter, stronger or easier to form. If these elements are not sufficiently mixed, cracks and fractures will form during processing, which will affect the performance of the final product. In metal production, heat is used to ensure that the individual metal elements in an alloy are well mixed in a step called homogenization.

During the homogenization process, large metal castings called billets are heated to nearly 500 degrees Celsius for up to 24 hours. This heat treatment step dissolves the alloy aggregates in the billet to ensure uniform distribution or homogenization of all metal elements. This improves the performance of the final product. After homogenization, the metal rods are further heated and shaped in a step called extrusion.

However, homogenization is the most energy-intensive step in the entire metal extrusion process.

This is where the ShaAPE process comes in.

According to Scott Whalen, chief materials scientist at PNNL and co-developer of the technology, the ShAPE machine eliminates the need for separate homogenization and extrusion steps by combining heating and deformation – changes in the ShAPE of the metal itself.

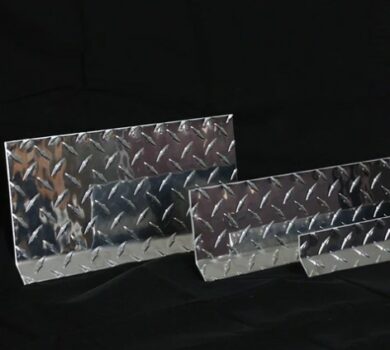

In the ShAPE machine, the metal billet is simultaneously pushed through a small opening in the rotating mold. When the metal element is squeezed, the rotational motion and deformation together thoroughly mix the metal element.

In other words, the new process homogenizes the metal stock in seconds, just before it is squeezed. This eliminates the need for a day-long preheating homogenization step and means that no extra energy is used to heat the billet during extrusion. Overall, this can save up to 50% of energy.

Whalen and his colleague Tianhao Wang carried out some performance tests and showed that their technique also improved the mixing of individual alloying elements, resulting in a better final product. In detail, the strength and elongation of components made from aluminum alloy machined by ShAPE exceed the current standards of the American Society for Testing and Materials.

“We used electron microscopy to take a closer look and found that ShAPE decomposed the alloy aggregates and dissolved them into the aluminum matrix before extrusion, making it easier to squeeze,” Wang said. “This translates into better performance – our 7075 aluminium alloy is stronger and stretches further before breaking.”