Aluminum sheets are the unsung heroes of several sectors, including electronics, aerospace, and building. Customers frequently encounter particular difficulties when starting projects involving aluminum sheets. In order to guarantee the success of your aluminum sheet initiatives, we’ll address some prevalent concerns in this post and offer useful remedies and ideas from Yikuo.

Selection of Materials and Customization

It’s crucial to select the appropriate aluminum alloy for your project. The characteristics of various alloys vary, from corrosion resistance to strength and formability. Start by precisely identifying the requirements for your project. After choosing the best alloy, think about your customization possibilities. To fit your unique demands, aluminum sheets can be customized with precise sizes and finishes. The secret to striking the ideal balance between material selection and customization is to work closely with your supplier.

Treatments and coatings for surfaces

When working with aluminum sheet, surface finish and coating durability are crucial factors to take into account, particularly in harsh settings or demanding applications. Corrosion resistance and attractiveness can be improved by applying advanced surface treatments like aluminum coil anodizing or color-coated aluminum. Working closely with your supplier is essential to ensuring that the chosen treatment is in line with the objectives of your project. Coated surfaces can have their lifespan and performance optimized by routine inspection and maintenance, resulting in long-term success.

Monitoring and Inspection of Quality

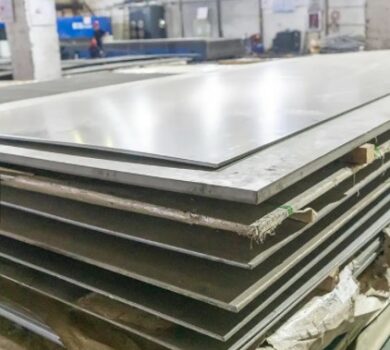

For a project to succeed, consistent sheet quality must be maintained. Automated inspection systems and other stringent quality control techniques can aid in the early detection of flaws and irregularities in the production process. Checking or doing major inspections of medium and thick aluminum plates is a must. It is equally important to perform routine calibration and maintenance on inspection equipment. The highest standards are met throughout your project by creating strong partnerships with your suppliers that are defined by open communication and frequent quality checks.

Budgeting and cost-effectiveness

Projects involving aluminum sheets are constantly concerned with cost effectiveness. Consider optimizing material consumption with cutting-edge nesting and cutting software, eliminating waste, and cutting material costs to address this. Modern cutting tools and software are an excellent investment since they greatly increase material usage, lower scrap, and increase cost-effectiveness. It’s crucial to strike a balance between cost effectiveness and quality, so think things through carefully and choose long-term value over immediate savings. With this, it is essential to master the craft of aluminum sheet cutting to have a better result.

In summary, projects involving aluminum sheets can be quite effective if they are tackled with careful preparation and cooperation from your suppliers. You can make sure that Yk aluminum material manufacturers cannot only meet but also exceed your expectations by picking the appropriate aluminum alloy, adapting sheets to your project’s needs, selecting suitable surface treatments, enforcing stringent quality control procedures, and managing expenses effectively. The achievement of success in these undertakings requires a commitment to delivering excellence in every application, not just a goal.