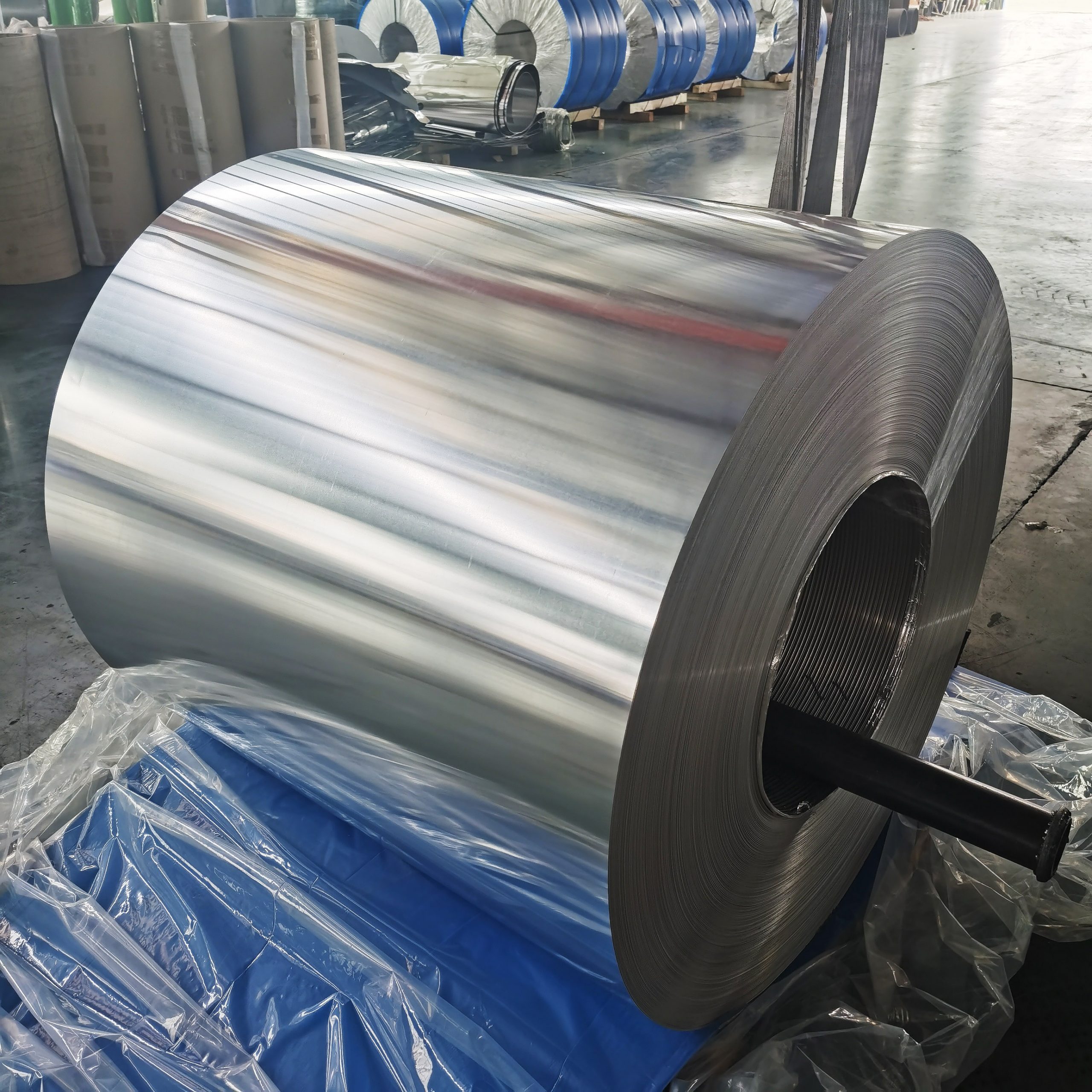

With years of experience in aluminum manufacturing and a dedication to assisting our clients in overcoming the difficulties of rolling aluminum sheets, Yk Aluminum is a reputable market leader. In addition to discussing typical issues encountered while rolling aluminum sheets, this article will also highlight several unique qualities that set Yikuo Aluminum apart from competitors.

Solutions to Common Issues

Issue 1: Surface Flaws

Surface flaws can be bad for the quality of the finished product, but Yk Aluminum provides a distinct advantage because of our cutting-edge facilities, which guarantee a controlled and hygienic atmosphere. Superior surface quality is the consequence, as the possibility of contamination and abrasive particles is reduced.The trustworthy partners in removing surface imperfections because of some of our features, like our precise lubrication systems and strict quality control procedures.

Second issue: Uneven Thickness

In the production of aluminum sheet, thickness consistency is crucial. Advanced gauge control systems at Tianjin Yikuo smoothly monitor and modify the rolling process to maintain consistent thickness all throughout. Our dedication to roller upkeep and knowledge of which aluminum alloys have stable qualities to choose are key factors in the consistency and dependability of our goods.

Third issue: Edge cracking

It takes aggressive steps to address the issue of edge cracking. When necessary, Yk Aluminum uses edge trimming procedures and annealing techniques to reduce the possibility of edge cracking. Our attention to material quality and meticulous roll pressure setting modifications help ensure the strength and robustness of our aluminum sheets.

Fourth issue: Wrinkles

Yikuo uses sophisticated tension control systems, processing rollers made for smooth operation, and precise entrance and departure guides to prevent creasing. The aluminum sheets are made with less wrinkling thanks to these qualities, making them appropriate for even the most demanding applications.

Features of Yikuo Aluminum That Stand Out

Cutting-Edge Technology:

The state-of-the-art equipment at the contemporary Yk factory ensures accuracy and consistency throughout the rolling process.

Quality Control:

Implementing rigorous quality control procedures at each level of production will quickly identify and address any problems.

Expertise in Material Selection:

The staff at Yikuo Aluminum meticulously chooses aluminum alloys that adhere to the strictest industry standards for uniformity and mechanical qualities.

Customized Solutions:

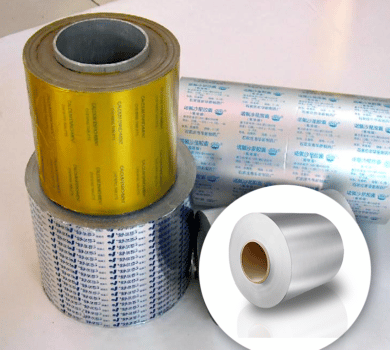

They are aware that every customer has different needs. Offering specialized solutions to address particular needs gives Yikuo Aluminum a competitive edge in the industry.

Environmental Responsibility:

They place a high priority on sustainability and environmental responsibility in all aspects of all business operations, using eco-friendly procedures all the way through the production process.

Conclusion

In addition to being committed to assisting clients in overcoming typical issues related to rolling aluminum sheets, Yikuo Aluminum specializes in offering exceptional characteristics that guarantee the manufacture of high-quality, reliable, and consistent aluminum sheets. Standing as the ideal partner for all of your aluminum sheet rolling needs thanks to cutting-edge technology, dedication to quality, competence in material selection, tailored solutions, and environmental responsibility. You can rely on Yikuo Aluminum to give superior service at every turn; just contact them right away.